Hello everyone, even though it’s already a few weeks into January, we didn’t want to miss the chance to wish you a Happy New Year!

We would like to start this report with a brief review of the past year. What has happened, what have we done, what is the current status and what is planned? Here is a quote to begin with:

“We are running the most dangerous experiment in history right now, which is to see how much carbon dioxide the atmosphere can handle before there is an environmental catastrophe.” – Elon Musk

In our last blog entry, we told you that after returning from CERN, we looked for other problem spaces and ideas through further ideation sessions. We also presented some of these in the article. At this point, we were at the tip of the first diamond, if you think of the double diamond process model. The next step was therefore to narrow it down, which in our case was to focus on a single problem space. When we were comparing our ideas, we ended up with an idea that we had already been pursuing at CERN and that was also our favoured there. The problem we are looking at is the high level of CO2 in the air. The idea is to use microalgae to remove CO2 from the air.

With that the problem was clear, but the problem space still needed to be defined more precisely, because the problem of too much CO2 in the atmosphere alone offers no real starting points. That’s why we first looked at Germany’s CO2 emissions, what developments there are and what the goals are. We then looked at the emitters of CO2 in Germany and finally found out that the production industry in Germany alone emits around 110 million tonnes of CO2 per year. Germany wants to achieve net zero emissions. To achieve this, industry must also join in. With this in mind, we set about creating the final presentation of phase 1.

In the presentation, we addressed the problem of the high level of CO2 in the atmosphere and the too slow decline in emissions in Germany. Next, we looked at the problem of CO2 certificates and greenwashing and came up with a how-might-we statement. This is:

How might we support the industries in achieving net-zero, without cheating?

After this statement, we presented our idea for the solution: a CO2 compensation system based on microalgae at the production site. This was followed by an initial assessment of the advantages of using microalgae. And with that phase 1 presentation was done!

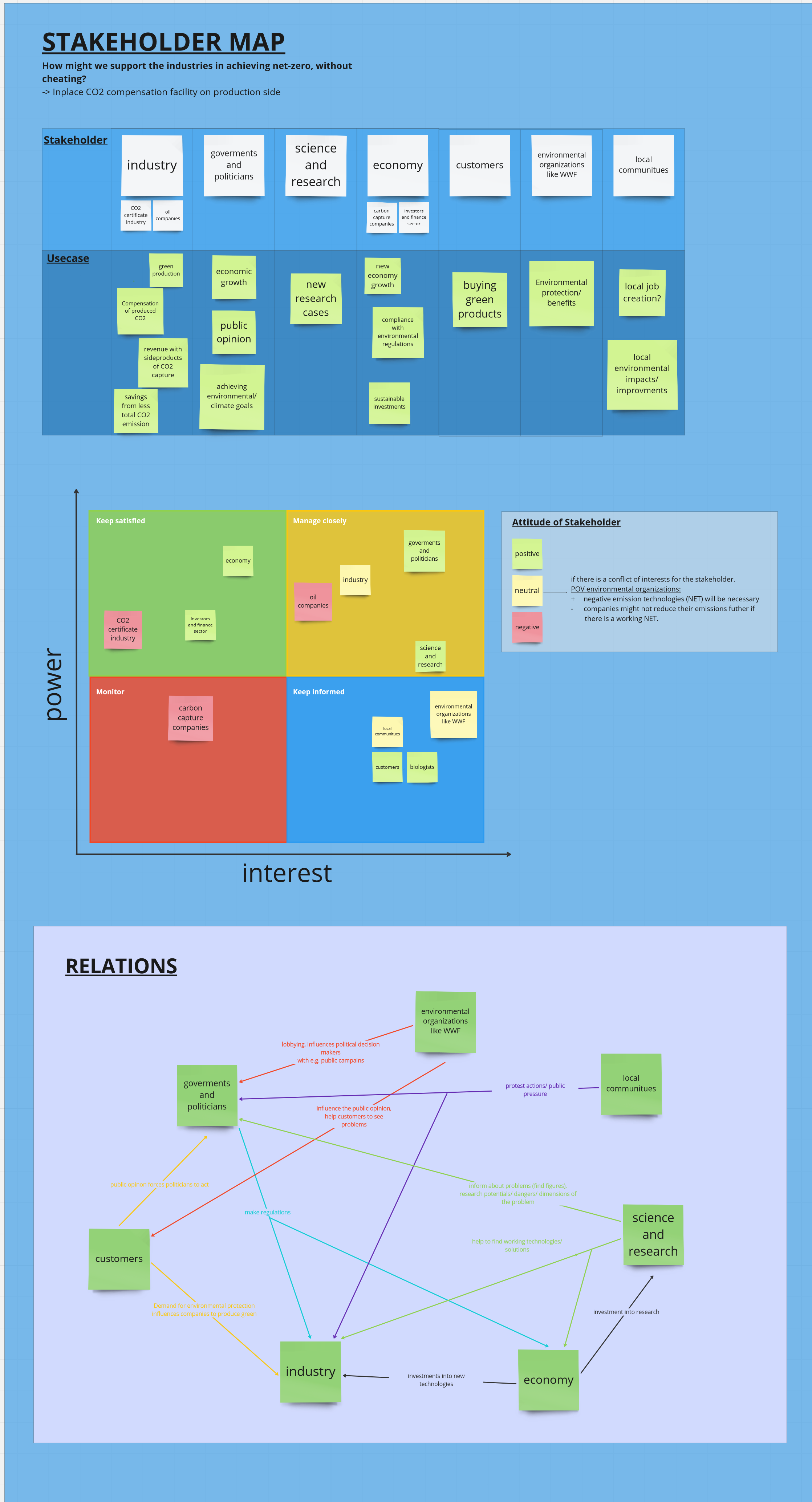

Building on the momentum from our phase 1 presentation, where we introduced our innovative CO2 compensation system using microalgae, we realized the importance of thoroughly understanding the broader context in which our solution would operate. In order to explore the problem and the solution in more depth, we then learned about stakeholder maps and created one. A stakeholder map is a powerful tool that enables the identification, organization, and understanding of the roles of individuals and groups within a system or community. By visually illustrating the key relationships between people, it provides a clear and concise overview of the stakeholders involved, allowing for more effective decision-making and strategic planning.

Next, we have taken an important next step by producing a white paper. This exercise is more than a formality; it is a strategic move to deepen our engagement with the project from the very beginning. Producing a white paper at this stage serves several purposes. Firstly, it gives us practical experience in producing such a critical document, an essential skill in any project lifecycle. Secondly, the process of writing the whitepaper requires us to think quickly, concisely and with a conscious focus on the direction of our project. It’s not just about documenting what we know; it’s about clarifying our understanding and approach. It forces us to clarify our thoughts, refine our ideas and articulate our vision and strategy in a way that is clear and logic.

To give you a short summary:

The White Paper begins with an introduction to the United Nations’ SDG 12, followed by a clear definition of the problem space. The result are the assumptions that current carbon emissions are too high, that they are decreasing too slowly and that reduction strategies such as carbon trading often only lead to greenwashing. Therefore, a novel approach using algae-based carbon sequestration systems (A.C.C.O.S) is proposed to help the industry achieve true net zero emissions.

A.C.C.O.S

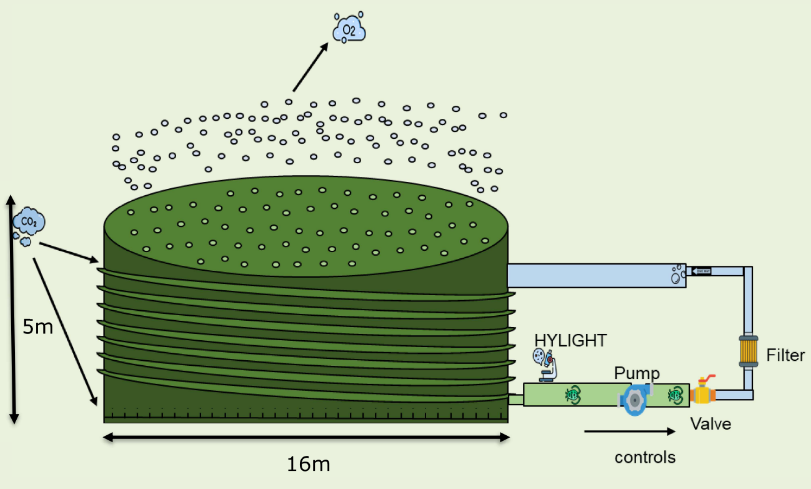

The idea of A.C.C.O.S, a system that embodies innovation and practicality, was developed. It’s an on-site CO2 compensation system that uses the natural process of photosynthesis in microalgae to compensate the CO2. The system includes a pond for algae cultivation, a pipe system for optimal CO2 retention and a filtration mechanism to maintain ideal algae density. It also includes safety measures such as additional ponds for excess CO2. Advanced technologies such as HYGLIGHT and CRISPR-CAS9 are intended to increase efficiency. The goal of the A.C.C.O.S is ambitious but achievable: A facility should be capable to capture up to 18,000 tons of CO2 per year. That’s equivalent to the output of a medium-sized industrial plant.

Mapping the way forward

Looking ahead, our immediate focus is on diving deeper into the different aspects. We want to build a prototype to closely observe and understand the behavior of algae, in particular their light requirements. In addition, we are committed to designing adaptable plant setups for different industrial applications and conducting a cost analysis to determine the economic viability of our system.

Recent Comments