Hello fellow innovators and designers, we’ve been off doing some radical thinking and challenging ourselves to think beyond the limits of 2024. The past couple of weeks we’ve learnt more about various disciplines and variables of design that has impacted a lot of our thinking and development positively. Technology trends, planet-centric design, systems thinking, behaviour change, technology deep dive, and responsible innovation are a few of many we were briefed about. Diving into these variables of design made us think outside the box to ideate varied solutions. We apologise in advance for the roller coaster of ideas we’ll be covering below but they were essential to land on our final solution!

In our previous post, we briefly swept through our primary research where we delved into the problem spaces in our topic of e-waste recycling in Melbourne. Our first prototype direction was to envision the future of 2050 where we will be able to communicate with VR glasses like the current Apple Vision Pro. A solution where we use a spatial computer that blends digital content and applications into their physical space and lets you navigate using your eyes, hands, and voice using the technology of Augmented and Virtual reality. From meetings to planning to watching a movie, etc. Regarding e-waste, we were looking at making information more accessible for consumers to recycle so it is easier and seamless. The tech will be able to display the cost and location of the repair. In addition to this, it will also be a learning platform that displays how much metal can be extracted and recycled from the electronic waste.

For our second prototype, developed during the planet-centric design session, we aimed to create a solution that would become obsolete once it had fulfilled its purpose. Building on this idea, we developed a smart bin to educate consumers about different types of e-waste and to encourage them to sort waste correctly. The smart bin, a single large container divided into four compartments, features lids of specific colours and a scanning function that identifies the type of e-waste and automatically opens the corresponding compartment. This design would help consumers to memorise the colour coding for a particular type of e-waste, while also helping to reduce the recyclers’ workload by pre-sorting the e-waste. This would lead users to relate the colour codes for different types of e-waste, the smart bin could be replaced with just colour coded regular bins.

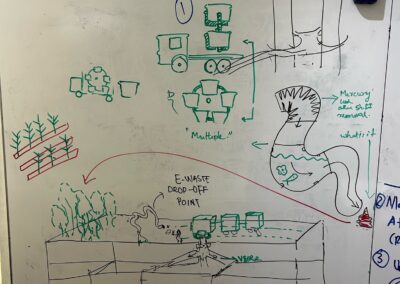

Our third prototype to the e-waste issue focuses on the disposal and collection points. Based on our surveys about why many consumers were hesitant to dispose of their e-waste, we discovered that convenience and data privacy concerns were among the main reasons for either hoarding e-waste or not disposing of it in the designated bins or facilities. Inspired by this insight and drawing from the Uber model, we devised a solution where consumers can schedule an e-waste pickup using an app. A truck equipped with drones will arrive at their residence to collect the e-waste, which is then sorted into the appropriate compartment within the truck. The drones play a crucial role in scanning and sorting the e-waste into the correct sections of the truck, as well as collecting e-waste from locations that are inaccessible to the truck alone, such as apartments or challenging areas. The app allows users to track the truck’s location and estimated arrival time, ensuring they only need to set out their e-waste when the truck is about to arrive. Additionally, we proposed a notification system that alerts other households along the truck’s route, enabling them to dispose of their e-waste if necessary. Our goal with this prototype was to alleviate consumers’ data privacy concerns and provide an easily accessible e-waste disposal solution.

Prototype 4 helped us dive back into the future of apple vision pro, but this time we looked into utilising the technology in the recycling facilities. We were able to get our hands on an X-real glass which helped us ideate on the future of vision pro and create a prototype that supports this idea. Batteries in electronic products cause fires and disrupt the recycling process of e-wase. We created a 3d graphic representation of a Kids toy with a battery in it that requires to be removed before sending it off for processing. This graphic was then viewed in 3D with the X-real glass which helps the manual labour dismantle the electronic products efficiently.

After having read through our prototyping journey you’re probably wondering where we’re headed. Dont worry, we’ll try to shorten the entire journey although getting to our detailed solution wasn’t as easy as it seemed at the time. There were times when we were beyond radical and wasn’t radical enough. Getting to the middle ground was what we struggled with most during the design development stage which we finally achieved with our E-green garden!

Our problem space:

Australia is one of the world’s top producers of e-waste, with 21.7kg of waste per person which accounts to 153 phones per person. Our e-waste output is growing 3 x times faster than our general waste output. Every year, 88 percent of the 4 million computers and 3 million televisions purchased in Australia end up in landfill, contributing to over 140,000 tonnes of electronic waste. Australia generated 520,000 tonnes of e-waste, of which, 240,000 tonnes was sent to landfill.

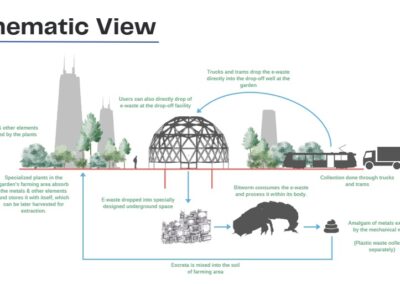

Our design detail presentation will give you an overview of the problem space and how our solution plays a role in tackling the issue of e-waste in landfills that do not get recycled. The solution is a recycling facility that will be placed in metropolitan cities around Australia which facilitates easy drop-off/ collection, recycles efficiently while extracting metals as well as disposing by-products safely.

The recycling process will also ensure the safety of workers and dispose toxins safely. To better understand this, lets breakup our solution into three parts. Our solution consists of three components:

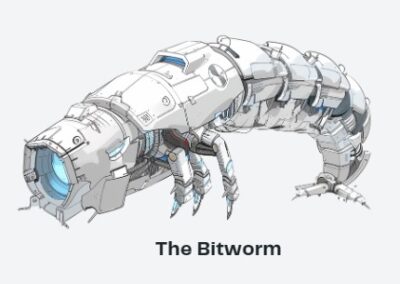

1. Recycling worm: In the development of the recycling mechanism for the underground e-waste space, we have drawn inspiration from one of nature’s smallest yet efficient creatures: the earthworm. Our solution features an automated electro-mechanical device designed to mimic a worm, which is capable of grinding e-waste into fine particles and then processing it internally. The device breaks down the crushed components using a combination of microbial and chemical solutions, facilitated by a specially selected culture of microbes. Any heavy metals present in the e-waste that cannot be processed by the microbes are expelled by the device, into a specialised section of the garden space designed for this purpose. Here, using genetically modified hyperaccumulator plants, these metals can be extracted through phytomining. Although this is a long-term process, we are confident that this safe and eco-friendly method of metal extraction will prove to be cost-effective.

2. Collection points: The image below displays the collection truck that we will be deployed fortnightly throughout the suburbs and urban areas of Melbourne. Melbourne trams being one of the most commonly used public transportation around Melbourne will also play a role in the collection system. It will have a seperate cabin dedicated for collecting the e-waste and dropping it off in the dedicated port of the recycling facility. A self drop-off point in the recycling facility will also be available for visitors to drop off their e-waste.

3. Garden: The recycling facility will be a dual recreational area with the underground recycling system below and the garden that is fueled by e-waste on the surface. The e-waste that is grinded by the recycling worm will be then used as a fertiliser for genetically modified hyperaccumulator plants where these metals can be extracted through phytomining.

Key points :

1. The impact of this on the environment is drastic. Electronic products contain a wide range of potentially hazardous substances, from lead contained in cathode-ray tube glass, to mercury in fluorescent lamps. Safely disposing them of protects workers from being exposed to these.

2. Chemicals of concern like lead and mercury can leak out of the electronic products and contaminate the soil and groundwaters. The safe seperation and extraction allows to prevent this.

Team snapshot :

Our design development was one of the most challenging parts of this semester. We were faced with up’s and downs and deliberating between lots of solutions. Let’s look at what we learnt:

Learnt about various variables of design which we hadn’t surprisingly heard of before the start of the design development!

Brainstorming kept us up day & night but it lead to some of the coolest out of the world solutions ( we had vivid dreams on e-waste).

Radical thinking had us viewing the future in various view-points but they’ve all been exciting!

Quote of the week :

“The past cannot be changed. The future is yet in your power.” – Mary Pickford.

Next steps:

Diving into the details is essential for us to move forward with a clear idea on what needs re-work or development. Some of the aspects we are keen to look into would be the development of the recycling facility over the years, what can be added/ improved, the size and overall functionality of the facility. We will be looking at the reviews by our teaching faculty and others at Ideasquare, NYC and Mannheim to define our direction better.

Thankyou for making it till the end, see you on the next blog post!

Recent Comments