Due to our Midway Presentation, we took a week’s hiatus to focus – so we’re catching up on 2 weeks’ updates!

Earlier in the month, we attended the first ever Port Phillip Bay Nurdle Hunt organised by Organisation Clean Sweep which aims to keep plastic nurdles out of the wider environment.

It was really eye-opening to see how much rubbish can be found in just a small space and within a small time. We also experienced first-hand the challenges with collecting them – styrofoam disintegrates as you hold it because it is brittle, organic materials and plastics are completely mixed and the sorting process takes five times longer than picking them up.

For our midway presentation, we chose to focus on synthetic tyre dust as a source of microplastic because 20,000 tonnes of tyre dust is released every year in Australia alone.

ReTyre is a device that can be attached to the undercarriage of a car. It works by attracting tyre dust via electrostatic cling. The friction of tyres on the road creates negatively charged tyre dust which is attracted to positively charged plates on ReTyre. The positive charge is generated through kinetic energy from the rotation of the wheel axle. When the engine is turned off, the positive charge is turned off too, and any attracted dust will be released into a funnel where it is vacuumed into a collection cartridge that can be emptied at service stations every 6 months during regular car servicing.

The collected tyre dust can be used to create porous asphalt, which has more capacity not only to trap microparticles like tyre dust to keep it out of stormwater but also to allow water to permeate through. This helps to avoid extreme flooding events and stops rubbish from being carried into the stormwater systems.

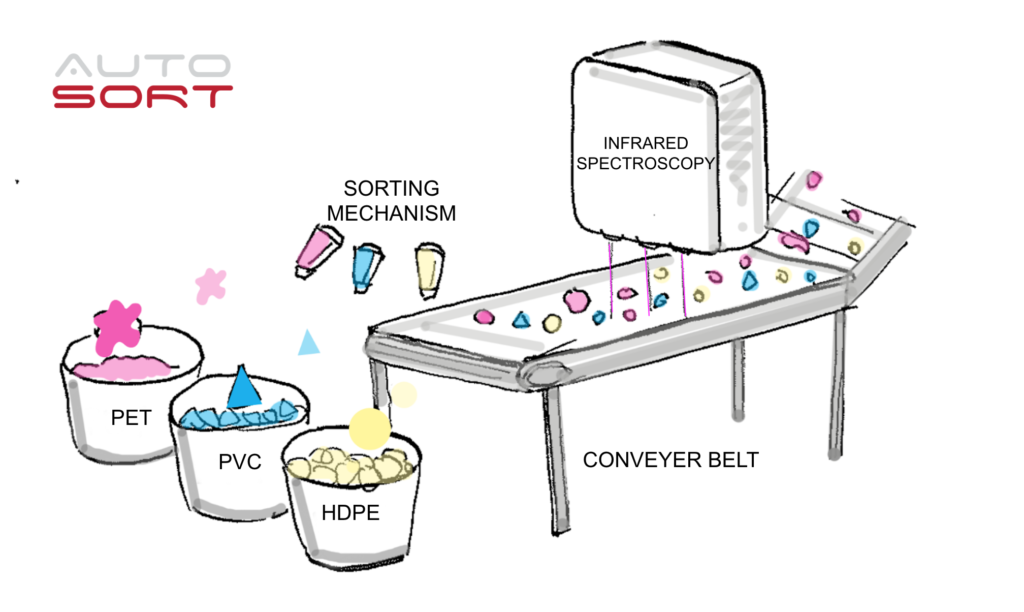

The AutoSort works autonomously to recognise and sort materials. Infrared spectroscopy is used to identify the material composition and a sorting mechanism separates the materials into different categories. It is backed by CERN’s ROOT software, which is capable of quickly processing large masses of sensor data. This data can then be fed into CERN’s robotics software which directs the sorting mechanism to separate the recyclables from other materials. We envision that this can be scaled down to be able to handle things even at nano-scale.

While we received generally positive feedback and suggestions, we would like to hear your comments – so please do leave us some below!

After the presentation, we decided to start making prototypes. Hence, we collected

We also spoke to Dr. Mahdi Disfani of the University of Melbourne who is working on a project to develop porous asphalt using used tyres. We learned a lot about what happens to used tyres, challenges with recycling tyres, and about how porous pavement and roads could help to reduce flooding incidents and potentially serve as a filter.

Currently, around 40% of recycled tyres are shipped overseas, only 5% are recycled in local facilities (to become tyre crumb used in playgrounds, indoor courts, etc.) and the remainder tends to go into landfill.

Dr Disfani estimates that if his porous asphalt product could be applied in just 2% of Australian car parks, this can channel 50% of tyres away from landfill.

Insights:

Great initiatives such as the nurdle hunt and other cleanup activities are being carried out, but there is SO MUCH waste out there and even when it is removed from the environment, it needs to be sorted, which is really time-consuming.

Initiatives like Operation Clean Sweep helps to keep plastic nurdles from entering the environment by working with plastic manufacturers to control and eliminate accidental spillage. This is effective for this particular source.

Feedback from the presentation includes:

-Static electricity as a way of collecting plastics/tyre dust is an interesting concept – could the motion of air caused by how the tyre spins help?

-Nanolevel sorting based on the level of contamination. This could possibly be classified by % of contamination. For e.g. if only 0.5% contamination then it can be channelled back to reuse, if around 80% then channel it into asphalt, etc.

-More attention needs to be paid to awareness raising and behaviour change. One example was to force people to change their habit by, for example, not collecting rubbish until people recycle properly.

-Porous roads are currently being trialled for low-traffic conditions. This has potential to be scaled up to high traffic loads.

-There is potential to engineer filtration into the porous road but this could affect the speed of water flow

-Environmental alternatives need to be financially attractive to be adopted

Interesting, but I am not sure if electrostatic would work. Maybe?

Most people we have spoken to

Next steps

- Play with electrostatic when our electrostatic science kit (for 12+ year olds) arrives

- Look into the sorting mechanism and work out the first prototype

- Use tools such as the Iceberg Model, SWOT analysis, futures and forecasting to focus our problem area

- Talk to Zoran (our Synchrotron contact) and Kathi (our CERN mentor) about our current concept

- Send out a survey to gauge public opinion on microplastics

References:

http://www.opcleansweep.org.au/news/267-2019-port-phillip-bay-nurdle-hunt

https://pursuit.unimelb.edu.au/articles/turning-old-tyres-into-new-roads

Using electrostatic to collect tyre dust is indeed a very interesting idea! I wonder how does it work in a rain though? Maybe it need to switch to collect&filter splashed water instead?

And about sorting mechanism, I don’t know if you already have a better idea in mind, but the requirements (I assume different types of small piece of plastics) make me think of when people try to clean impurities from harvested rice. There seems to be this think called “rice destoning machine”: https://grabcad.com/library/rice-destoning-machine-1. May or may not applicable to your case though.