With 3 weeks to go – we are very conscious that it’s crunch time! We have locked in very concretely onto our idea of the curbside robot, named Kirby (haha, get the pun?) who is a toddler-sized autonomous sweeping robot that focuses specifically on curbside dust (in between cars and all those hard to reach places) to make sure that nasty debris doesn’t enter stormwater.

These next weeks are all about GETTING DELIVERABLES DELIVERED. We have the rough design of Kirby locked in and did some reading on the technology we want inside him. We have also planned the details of what we will be showcasing on 2 May to convey our idea. We are being ambitious and expect some really hectic weeks!

In a nutshell (without giving too much away), we are building an awareness piece with an interactive component to help visualise the invisible issue of microplastics, specifically tyre dust. We will also talk about the parts of the system that contribute to solving our problem, including the initial electrostatic plate idea and finally how Kirby is the main star of the day. We won’t have a working Kirby, but he will be present in some way, shape and form!

Paris (our teaching team) has very kindly shared her designerly skills with us to help us with thinking how to actually plan out the dimensions of Kirby. With her help, we now have a better concept of how to make a scale model of him.

We are also working on the timelines that make Kirby possible – what are the conditions that will lead to realisation of the need and benefit of Kirby?

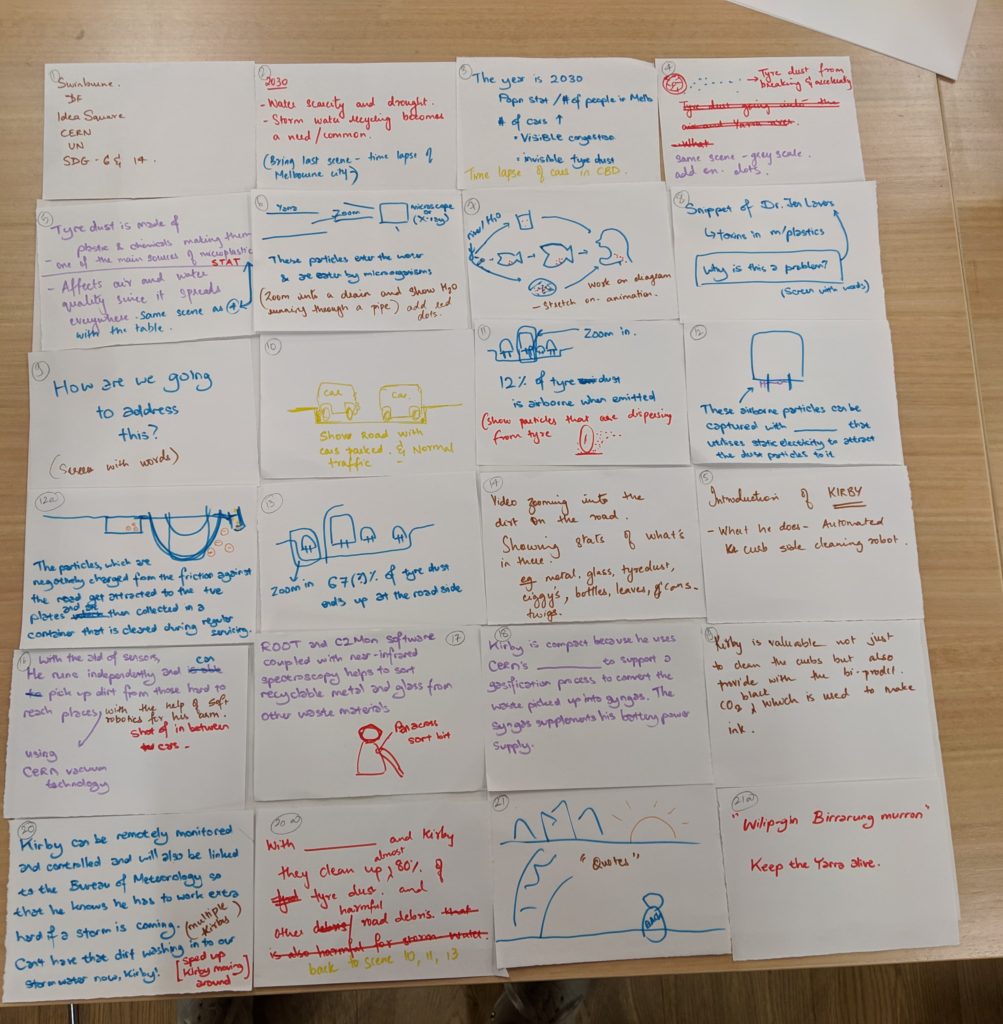

We are also required to create a video explaining our concept, and for this, we have created a storyboard mapping out what we intend to convey. Our video genius Leinard also from the Design Factory has kindly stepped up to help us out (you cannot understand the relief this brings) and we are looking forward to working with him on bringing our concept to life!

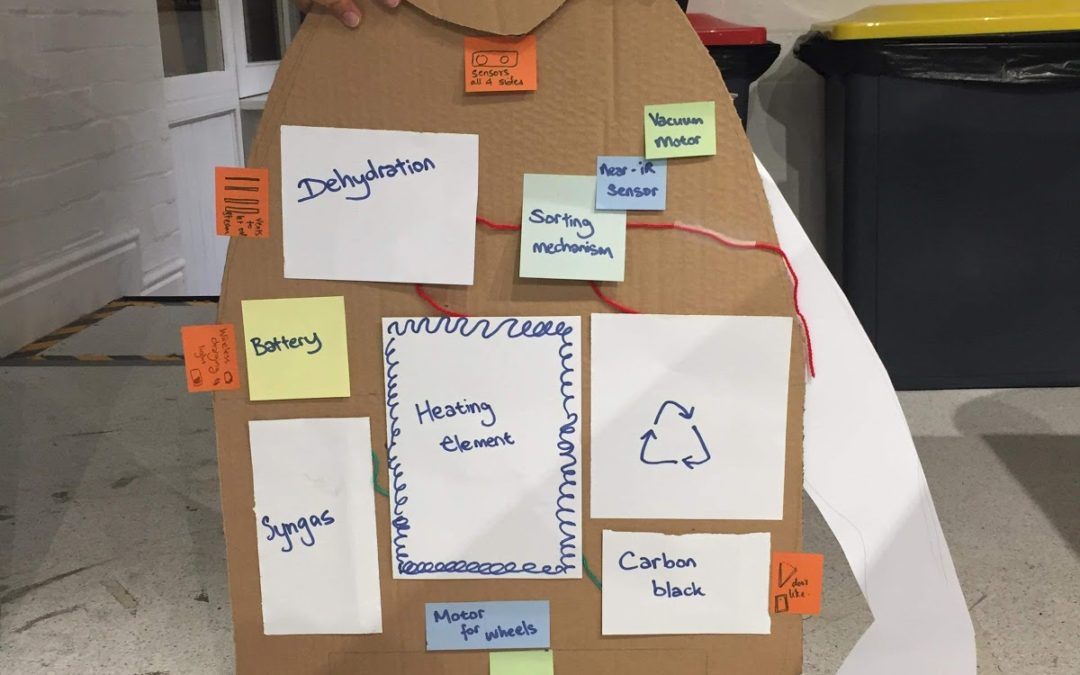

With a time crunch forcing us to deliver as much as we can, we prototyped a 2D model of Curby. We cut out the internal functions of Curby so we understand the internal system better. This also helps us convey to our 3D modeling guru Paris about our dimensions as well as help us visualize how Kirby would look on an actual curb running next to a car.

This helped us focus details of him as well. Example, where will the light sensors be placed, the location of the battery and where to access the carbon black from.

Another idea to showcase our “static plates below fleets” is to laser cut a bus or truck for the showcase. To this, we would fit our static plates. We foresee, this would help people visualize where static plates would be retrofitted on existing vehicles.

Aaarrgghh!! Less than a month! So much to do!

Panicky Team Spring

Next Steps:

- Create the storyboard sketches for the video

- Systems mapping

- Pending details of Kirby like- how does it know when to cross the road?

- Finalize which CERN tech we are using where -have a call with CERN mentor Kathi

- Stop calling it the static plate concept – give it a name!

- Work twice as hard so we can enjoy the Easter break

I love this post! Saw your team video- it’s great!